Background

There are many types of overflow setups for use in aquaria, most have inherent design flaws or shortcomings that we just accept and live with. The most common problems are noise and reliability. Many a reefer loses sleep at night due to noise or worries of a flood caused by a malfunctioning or clogged overflow. In addition to the noise and instability, most types of standpipes introduce large volumes of bubbles into the sump that find their way to the return pump and back into the display.

My tank is an in-wall design that is setup in the rear wall of my home theater. The equipment side of the tank is a small room adjacent (and open) to my home office. Noise of any kind is simply not an option that I can live with. Furthermore, during the initial setup phases of my system I had a few small floods.

After doing a lot of research I learned that long overflow boxes are desirable for their superb surface skimming abilities. With some advice from Anthony Calfo (who is also a local club member!) I settled upon a coast-to-coast overflow design, A.K.A a Calfo Overflow. Anthony is a huge proponent of maximizing surface skimming. Based on observation and available data (some of it Anthony’s own) I agree with his conclusions.

To make a long story short, I was unable to silence the overflow. I attempted several Durso and Stockman style modifications and many variants thereof. It quickly become clear that all of these methods still produce noise and that the quieter they are, the less stable they are. The reasoning is simple. The Durso and Stockman modifications are simply means of changing where the air enters the standpipe. Water falling down through a pipe will pull air with it. If it can not pull air, it pulls more water and creates a siphon that quickly empties the overflow box. We all recognize this as the flushing sound that an unmodified standpipe (or out of adjustment Durso/Stockman) makes. The setup is a balancing act that is never really quite or stable at the same time.

Standpipe Basics

A standpipe can only run silently under two conditions. 1) The volume of flow is low enough to allow the water to cascade down the walls of the standpipe, leaving an undisturbed column of air in the middle. When water falls vertically down a pipe, the water will adhere to the pipe’s walls until the pipe’s cross sectional area is about 1/4 full. At any higher volume the flow starts to become turbulent and traps air. The trapped air creates slurping and gurgling noises. 2) The volume of the flow is high enough to keep the pipe entrance submerged, creating a full siphon.

So to revisit, the Durso and Stockman mods are simply ways of trying to control the amount of air introduced into the standpipe, creating a balance somewhere between turbulent flow and a full siphon. This makes the setup very unstable and requires constant adjustment, not to mention that the setup is never truly silent or safe!

Overflow Basics

The primary goal of an overflow system is to move water from the display tank to the sump. The sump is where many people incorporate primary or secondary mechanical and biological filtration. Foam fractionation (the skimmer) is a common filtration component that is placed in the sump. Research has shown that the thinner the sheet of water traveling over the overflow weir, the more protein rich the water is. Put simply, the organics in the tank like to bond to the surface tension of the water at the air/water interface. The faster we renew this thin layer of surface water and transport it to the sump, the better the skimmer will perform. It follows that for a given flow, the wider the weir, the thinner the sheet of water that flows over that weir will be. This is exactly what we want for our aquarium! The faster we pull the organics from the display tank into the skimmer, the faster we can remove them before they are consumed by algae in the tank. See the “Surface Renewal” inset for an example.

Websters Dictionary:1 : incorporating some feature for automatically counteracting the effect of an anticipated possible source of failure 2 : being or relating to a safeguard that prevents continuing on a bombing mission according to a preconceived plan 3 : having no chance of failure : infallibly problem-free fail-safe solution for night – Vogue

The Calfo or Coast-to-Coast style of overflow is simply an “L” shaped shelf that spans the entire length of the tank and acts as an overflow box. The shelf is sealed to the back and side walls to form the overflow box.

Design Goals

Using what we know, the ideal setup will either incorporate a standpipe that is large enough to produce cascading flow with an undisturbed column of air in the center of the pipe, or a standpipe that incorporates a self adjusting full siphon. Up-sizing the standpipes is certainly an option but in reality silence will be very hard to achieve with any reasonably sized pipe and bulkhead combination. Creating a self tuning siphon is also a daunting task.

I decided that I need a standpipe setup that meets the following criteria:

- Dead Silent Operation

- Fail-Safe to Prevent Floods

- Set and Forget Usability

- Limit Micro Bubbles in Sump

- Easy to Clean and Maintain

- Off the Shelf Plumbing Parts (no custom fabrication)

- Stable Over a Broad Range of Flow Rates

- Scalable to any Size Tank or Plumbing

I applied the basic flow principles used in water treatment and similar industries along with concepts currently used by other reefers. I came up with a design that is 100% silent and fail-safe for just about any type of failure or group of failures that could be imagines.

[WPSM_INFOBOX id=2785]The Solution

The solution was simple. Incorporate a siphon into the overflow setup and back it up with an open channel standpipe. If the siphon is adjusted to a flow rate that is slightly lower than what the return pump provides, then water will backup in the overflow box and be handled by the second (open channel) standpipe. If the system is adjusted properly then the volume of water flowing through the second standpipe will gently cling to the walls of the pipe and be silent. A benefit of such a setup is that the siphon standpipe can handle a significantly higher flow than an identical standpipe that has water mixed with air. I added a third standpipe to the system that stays dry during normal operation. This third standpipe provides some of the fail-safe features that allow for either of the two primary standpipes to become fully clogged without causing a flood or system malfunction!

System Description

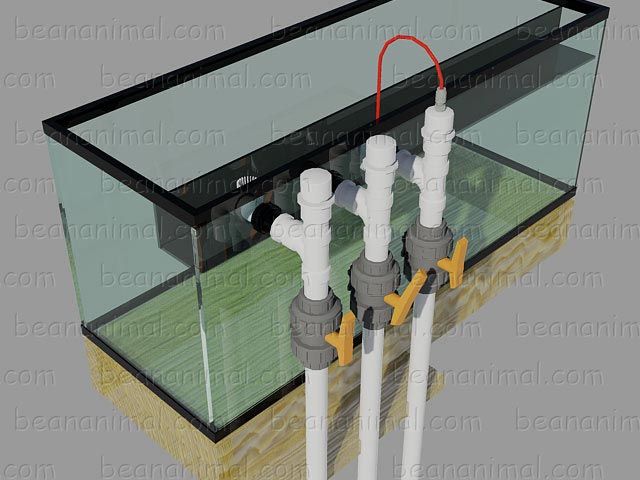

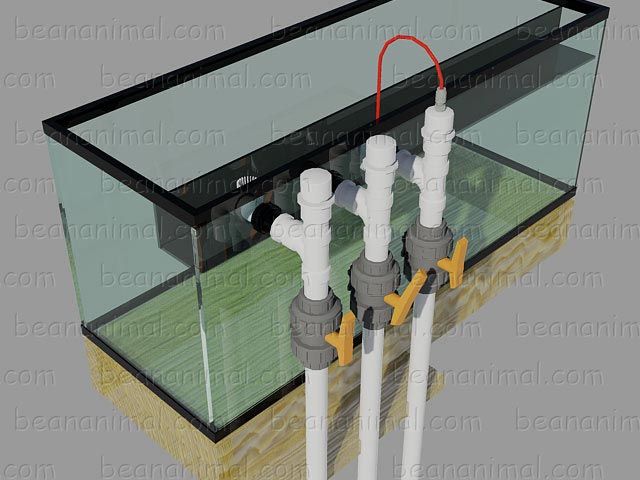

All of the standpipes are built with 1.5″ PVC fittings (adapted to the 1″ bulkhead with a bushing). I worked with the 1″ bulkheads that I had, but larger bulkheads are perfectly suitable. Each standpipe consists of a Sanitary-Tee topped with a threaded adaptor and a screw on cap. True union ball valves below the Tee are for adjustment of the system and/or isolation of the display if needed. The only valve that is truly needed is the one on the Siphon (middle) standpipe. The other standpipes have valves for versatility and isolation of needed. The Open Channel standpipe (right) is fitted with an airline that is curled back over and attached just below the trim inside the overflow box (more on this later). All caps are sealed with Teflon tape so that they are airtight. The siphon and open channel standpipes are fitting with down turned elbows and the emergency standpipe is fitted with an upturned elbow or and, optionally a strainer. All three standpipes are routed to the sump and terminate slightly below the waterline.

Rendering of the overflow system, showing the standpipes and overflow box from the rear of the tank.

From Left to Right

- Emergency Standpipe

- Full Siphon Standpipe

- Open Channel Standpipe

Something to keep in mind with this design:

A submerged drain that is running at a full siphon will handle MUCH MORE flow than a similar drain that allows air in. This setup, with the 1″ bulkheads and 1.5″ down plumbing will easily handle 2000 GPH silently with plenty of headroom to spare, while still keeping the emergency overflow dry. Try that with two Stockman or Durso standpipes!

How it Works

Both the Emergency (left) and Siphon (middle) standpipes are capped. During normal operation the valve on the Siphon (middle) standpipe is adjusted (as shown in the rendering above) until the water level in the overflow box rises high enough that air is not being sucked into its down-turned elbow. This means that the standpipe is running at full siphon with NO air being sucked in. This is DEAD SILENT. However, it also means that the standpipe is NOT handling all of the flow from the return pump. This is where the Open Channel (right) standpipe comes into play. The Open Channel (right) standpipe is open to the air via the airline attached to it. Because air is allowed in and the overall flow is fairly small (the siphon standpipe is handling the bulk of the flow), the standpipe will not siphon or gurgle. In other words, the small amount of excess flow that is not being handled by the Siphon (middle) standpipe quietly flows through the Open Channel (right) standpipe. Because the flow is very low, very little air makes its way to the sump.

This setup is absolutely set-and-forget! It is self tuning over a very wide range and does not need to be touched once set. It operates silently and introduces very little air into the sump (if any). The caps can be removed to clean the standpipes if the situation ever arises. The system is self tuning over a wide range because the siphon is not adjusted to the very edge of its operating capacity. As the average flow from the return pump rises and falls, the open channel standpipe will handle the varying flow.

Fail-Safe Features

The setup has (2) fail-safe features.

1) The Emergency (left) standpipe is set at a level slightly higher than the normal operating height of the overflow box. It is simply an up-turned elbow or strainer. If the water level rises above the normal operating level then it will flow down the Emergency (left) standpipe. This standpipe is also airtight. If the water level rises high enough the standpipe will begin to siphon and flush the overflow box.

NOTE:The Emergency (left) standpipe will also kick in during system startup. It takes a few moments for the air to be purged from the Siphon (middle) standpipe, during which time the water level in the overflow box may run high and into the Emergency (left) standpipe.

2) The Open Channel (right) standpipe is equipped with an airline that is attached to the high water line in the overflow box. If the water level rises to the critical point of overflow and the Emergency (left) standpipe can not handle the flow (say due to blockage from algae or something) then the water will cover the inlet of the airline. The flooded air intake will in effect convert the Open Channel (right) standpipe into a full siphon standpipe, allowing it to handle much more flow. This will flush the overflow box and prevent flooding.

THe elegance of the system is not only each individual safety feature, but the manner in which the standpipes (and their safety features) interoperate. The standpipe system dynamicaly changes its mode of operation to accomodate almost any adverse flow situation safely.

That’s it… simple and effective!

Notes

This system MUST use the (3) standpipes that are described above. The emergency standpipe is a CRITICAL part of this design. Omitting the emergency standpipe is asking for a flood!

Here are some other renderings that show some of the detail. I prefer to have the strainers touch the bottom of the overflow box. I used a table saw to fabricate them out of street elbows, but this is not needed for proper operation. No snails or fish can get into the standpipes. If your overflow box is deeper, then standard bulkhead strainers or those from a place aquaticeco.com or another vendor can be used.

|

|

|

|

Click on an image to enlarge: Birdseye view of the tank from the front (far left) showing tank, standpipes and the Calfo overflow. Rear view (left center) of the standpipes without the tank or overflow. Another view, this time from the side (right center) of the standpipes with the tank and Calfo overflow hidden. An exploded detail view (far right) showing the parts and assembly detail of a single standpipe.

The CAP on the Open Channel standpipe was drilled, tapped and then threaded to accept a standard John Guest airline fitting.

All (3) standpipes extend into the sump and terminate just below the water level.

This system has been in operation on my tank since November of 2005 and is handling 2000 GPH silently. The siphon or open channel valve can be fully closed and the system continue to operate without flooding the floor. For the system to flood, two standpipes would have to be fully blocked!

The overflow system starts flawlessly every time. The return pump is powered off every day during feeding time. Once power is restored, the system stabilizes and quiets down in 2-3 minutes (once all of the air is purged).

The design was published here and also in the BeanAnimal Silent and Fail Safe Overflow thread at Reef Central. The original thread quickly grew and the BeanAnimal Overflow thread split at Reef Central contains the most recent updates. If you are just starting, please read at least the first several pages of the original BeanAnimal Overflow thread before jumping into the latest BeanAnimal Overflow discussion.

Please note: I will not answer email questions or private messages at RC regarding this design, I simply do not have the time. Posting at ReefCentral will allow others to benefit from the questions and answers. Please use the threads linked above for support.

saw you in Reef Nerd YouTube channel video.. I need to transition over to something like this, especially if it is that silent….