This article is an extensive technical overview of High Intensity Discharge lighting technologies. Much of the content for this article, including the drawings and photos, have been made possible by Paul Erik Hirvonen.

HID Lighting Defined

High-intensity discharge (HID) lamps create light by forming an electric arc between tungsten electrodes contained inside a quartz or fused alumina tube. The arc tube is filled with metal salts and gas. The gas supports the initial arc and helps to heat up and evaporate the metal salts. The evaporated metal salts create a high intensity plasma arc.

HID Lamp Types

There are four basic types of HID lamps. Mercury Vapor, Low Pressure Sodium, High Pressure Sodium and Metal Halide. Each lamp differs in its shape, gas charge and details of operation. Metal Halide lamps are the primary type used in the reef hobby. The basics of the other types will be covered for continuity and context.

(click to enlarge)

Mercury Vapor (MV) was the first HID lamp. It was introduced in the 1930’s. MV usually has an outer bulb and an inner bulb (arc tube). The arc tube is made out of quartz and contains mercury and argon gas. A mercury vapor arc tube normally has three electrodes. One electrode (starting electrode) is used for starting the main arc. The ballast ignites the bulb using the peak/OCV voltage. When electricity is passed through the mercury/argon mixture iy produces blue/green light. Modern mercury vapor bulbs are available with a phosphor coating that balances the light spectrum and improves the CRI making the emitted light appear white. Clear MV bulbs with an added blue glass filter will work as a black light.

MV lamps are now commonly being replaced with other HID lamp technologies with improved efficiency or color rendering. MV is the least efficient of HID family. Some MV (self ballasted) lamps can directly replace incandescent bulbs without the need of a ballast. These MV bulbs use a filament for power regulation. MV lamps are manufactured in many shapes (PAR, R, ED, BT, A, T). One reason MV is still used today is because the rated bulb life is very good (some 24,000+ hours).

Mercury Vapor Usage:

- Replacing incandescent lamps

- General indoor lighting

- General outdoor lighting

- Security lighting

- Aquarium (non reef) lighting

- Plant lighting

The Low Pressure Sodium lamp (LPS) was developed in Europe in the 1930’s. The LPS lamp is not a true HID lamp. The LPS operates like a low-pressure mercury/argon tube (Fluorescent). These lamps were very popular in Europe but never gained significant popularity in North America. The LPS lamp has an inner bulb and an outer bulb. LPS lamps use neon/argon gas to start up and contain sodium to produce yellow light. The bulb needs a special inner bulb because standard glass / quartz glass can’t withstand metallic sodium.

The lamp may be started by an ignitor, or without the ignitor if the ballast has a high enough peak / OCV voltage. Light output is monochromatic 589 nm. The 1800K color temperature is one of the primary reasons that the LPS never took a foothold in North America. Everything under LPS lighting is cast in a yellowish gray tone. Some cities/states are starting to use LPS lamps to decrease light pollution. The LPS bulb was improved by putting a reflective coating on the outer bulb to reflect heat back into itself. LPS is the most efficient HID lamp (100-183 Lumens per Watt). LPS bulbs are commonly available in 18 – 180 Watts and only in tubular shapes.

Low Pressure Sodium Usage:

- Non-color critical lighting

- Outdoor lighting

- Security lighting

- Road lighting

The High Pressure Sodium (HPS) lamp is a high-pressure version of a LPS lamp. The higher pressure makes the lamp less efficient but produces a more pleasing light. The arc tube material can’t be made out of quartz because of the sodium ( the as the LPS). The HPS lamp came nearly 30 years after the development of the LPS and is a result of development of an arc tube to that can withstand sodium at high pressures.

The HPS lamps start up by using an ignitor and/or argon gas. Most HPS lamps need an ignitor to provide a starting voltage of 2.5kV or more. Special lamps are available that use the ballast peak/OCV voltage for starting (cutting production and maintenance costs).

HPS has become extremely popular everywhere because of its 90-140 Lumen per Watt efficiency. It also has a more balanced spectrum than its LPS sibling. A standard HPS lamp produces a golden colored light with a CRI around 20 and a color temperature of 1900-2100K. Modern HPS lamps are manufactured with a higher color temperature and an improved CRI. HPS lamps are manufactured in many shapes (R, T, ED, BT, DE) and commonly available in sizes from 35-1000 watts.

High Pressure Sodium Usage:

- General lighting

- Indoor lighting

- Outdoor lighting

- Road Lighting

- Plant lighting

Metal Halide (MH) lamps were introduced in the 1960’s primarily for industrial use. Like the other members of the HID family, MH lamps are high pressure/high temperature arc lamps with an inner quartz arc tube and and outer glass envelope.

MH lamps come in two basic flavors, probe start and pulse start and cover a wide range of lamp and ballast configurations. Probe start bulbs use ballast peak/OCV voltage to start the arc and pulse start bulbs use an ignitor.

MH lamps have become exceedingly popular due to their wide range of spectral options and wattages that are available. The lamps are now commonly used in commercial and residential applications where high output and efficiency are desired. Lamps now come in double ended versions as well as the standard mogul (screw type base).

Metal Halide Usage:

- High-bay lighting

- Outdoor lighting

- Road lighting

- Aquarium (including reef) lighting

- Plant lighting

- Projector lighting

- Fiber optic lighting

- Medical lighting

HID Startup Characteristics

Mercury vapor and probe start metal halide bulbs use the peak voltage/OCV to start the lamp. The high voltage and current needed to create the initial startup arc causes a lot of wear on the electrodes. When the arc has stabilized and the lamp is operated horizontally, the arc takes in a natural bend. For this reason, some bulbs have curved arc tubes to improve light output for horizontal operation.

Ceramic MH, standard European MH, pulse MH, and double-ended MH normally use this pulse (ignitor) method for starting. This method usually provides better lamp life and lumen maintenance because the ignitor causes less stress on the main electrodes vs. probe start (the ignitor uses high voltage but less current). Bulbs designed for ignitor + ballast should not be used on standard probe start ballasts (American ballasts). This can cause excessive stress on the electrodes or the ballast will not be able to start the bulb. That said, some probe start bulbs seem to operate on ignitor + ballast systems but some bulbs arc OUTSIDE of the arc tube! This may shorten the life or even short out the ignitor. If the bulb was made in Europe and the specs say to use 4kV for starting, then an ignitor must/should be used.

HID Ballast Types

The purpose of the HID ballast is to regulate the voltage and current that are provided to the lamp during startup and under normal operating conditions. Each type of bulb requires a specific set of starting and operating parameters. This section focuses on magnetic ballasts. Electronic ballasts will be discussed separately. The most common type of magnetic ballast used in North America is the Constant Wattage Autotransformer (CWA).

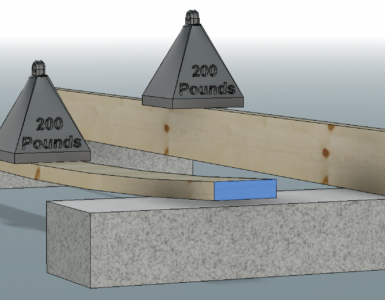

Magnetic ballasts come in two basic styles, the core & coil and the f-Can. Core and coil ballasts are pictured above and consists of a transformer, capacitor and possibly an ignitor. Many commercial applications use the core & coil ballast because the parts are easily replaceable. The components must be placed inside a suitable metal enclosure. The enclosure helps prevent fires and shields other equipment from interference. An enclosure is not optional!

F-Can ballasts have the same basic components but they are sealed (potted) in an epoxy or tar like compound. Many people refer to these as TAR ballasts. The potting compound allows the ballasts to be used as-is, without the need for an external enclosure. The compound also help keeps noise to a minimum by preventing the core from buzzing or vibrating.

(R)

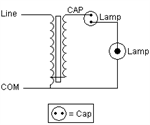

The Reactor ballast is the simplest HID ballast circuit. A reactor ballast consists of one coil that regulates power and does not transform the voltage. This means the ballast input voltage must be the same as the OCV or higher than the required OCV. The R type is commonly used in Europe because the input voltage is higher than in North America.

(CCR)

The Controlled Current Reactor ballast is in the same family as the (R) reactor ballast and replaces CWA style circuits in some instances.

(HX-HPF and HX-NPF)

The high reactance autotransformer ballast uses two coils. One coil transforms the voltage while the other regulates current. This ballast performs like the (R) ballast but works at lower input voltages and normally has multi-voltage input.

(CWA)

The Constant Wattage Autotransformer ballast uses two coils and is frequently referred to as a lead style ballast. The biggest difference from the reactor and HX-HPF is that the capacitor is connected in series with the ballast secondary coil or in series with the lamp. This ballast offers better power regulation than the reactor and HX-HPF/HPF-NPF. The down side is the CWA ballast is larger, less efficient and sometimes more expensive to manufacture.

(CWI)

The Constant Wattage Isolated transformer is similar to the CWA but the primary and secondary coils are electrically isolated from each other. These ballasts are more common in the Canadian market because of the Canadian Electric Code. These ballasts are normally larger and less efficient than the similar CWA ballasts.

(Regulated Lag)

The magnetically regulated ballast is one of the most sophisticated circuit designs. The Regulated Lag ballast uses three coils to provide the highest power regulation to the lamp. This ballast circuit is beneficial for lamp life and lumen maintenance. It is larger and less efficient than other types of ballasts available. This ballast overcomes many problems with input voltage variations.

HID Ballast Notes

CWA with the cap in series with the lamp only have been known to over ride some MH AND HPS lamps. European MH lamps are usually designed for R/HX (eactor/high reactance auto transformer) ballasts. When operated on CWA (CWA with the cap in series with the lamp only) these lamps have reduced lamp life and are notorious for cycling on/off (the lamp warms up and then turns off.)It is very important to match lamps with the proper ballast system. Each lamp has its own requirements. One ballast system will not operate all types of lamps properly. A ballast cannot be manufactured to match all the requirements. If the lamp requirements are not met (like using a lamp not designed for that ballast) less light output and/or shortened lamp life or other problems could occur.

Ignitors

Some lamps need ignitors for proper starting. Standard High Pressure Sodium and some Metal Halide lamps need ignitors. Low Pressure Sodium lamps may need an ignitor to light up (depending on the ballast type and open circuit voltage). The ignitor provides the proper starting voltage to the lamp. The voltage depends on the ignitor and ranges from ~600V to 6kV.

Most European MH lamps require the use of an ignitor. Standard North American MH lamps usually do not need or should not be used with ignitors. Using pulse ignition MH lamps on non-ignitor systems could cause premature lamp failure. A standard North American ballast (non-ignitor system) will cause excessive stress on the electrodes. Some pulse ignition lamps may not even light on these ballasts.

Standard North American MH lamps use the Open Circuit Voltage (OCV) for ignition. This type of starting is extremely stressful on lamps. The ballast provides the lamp with the proper voltage (like an ignitor) but with higher current. Lamps designed for this type of starting will have an extra electrode. This electrode (starting electrode) starts the lamp and is usually connected to a switch or resistor inside the lamp.

Mercury Vapor operates like the Standard North American Metal Halide (self-starting)

Add comment